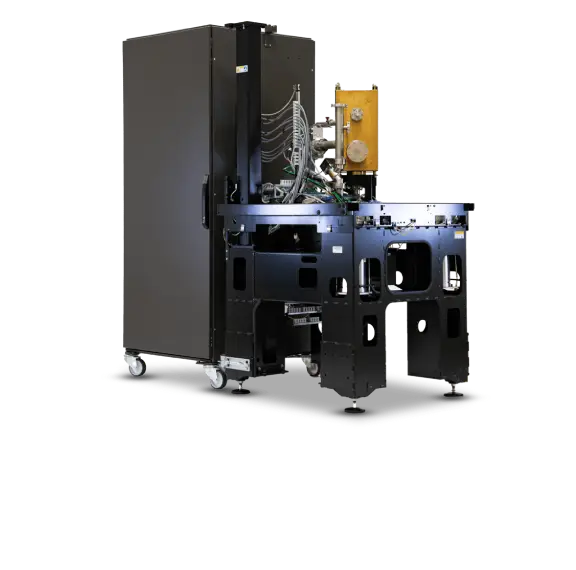

Phenom electron microscopes

for Thermofisher Scientific

Certified cleanrooms, modern technology and precision

Assembly of vacuum, mechanical, and electronic modules for scanning

and transmission electron microscopes and spectrometers—in accordance

with customer specifications and processes.

System integration and testing in cleanrooms in accordance with customer requirements

At our specialized facility, we perform complete system integration of electron microscopes.

We focus on high-level assemblies as well as mechanical and electronic assemblies for scanning and transmission electron microscopes and spectrometers. Our services include end-to-end material procurement logistics, supply-chain design and management, production engineering preparation, assembly, and testing.

Our expertise in electron microscopy and spectrometry is supported by an experienced R&D engineering team.

Our clean rooms meet high standards According to ČSN EN ISO 14644-1:2015:

- Area 1 550 m² - ISO 8 class (100,000 dust particles of 0.5 μm size per 1 ft³ of air)

- Area 150 m² - ISO 7 class (10,000 dust particles of 0.5 μm size per 1 ft³ of air)

With modern equipment, we deliver a high standard of services:

- Vacuum test using helium leak detectors Pfeiffer HLT550 and HLT265

- Residual Gas Analysis (RGA) - mass spectrometer Prisma plus QMS 200 F

- Full functional testing of assemblies, units, and modules

Technological Equipment

Equipment for precise cleaning of vacuum parts made from various materials (stainless steel, aluminum, copper, brass, titanium, plastic, rubber, painted surfaces).

The modern Pluritank 190 ultrasonic cleaning line is suitable for cleaning both smaller and larger components, including threads. The advantage is separately adjustable ultrasonic frequency and intensity along with automatic temperature and liquid conductivity measurement.

Technical parameters:

| Maximum installed power | 85 kW |

| Overall line dimensions | 16,2 × 3,4 × 3,25 m |

| Internal basket dimensions | 426 × 456 × 550 mm |

| Basket capacity | up to 50 kg |

| Bath volume | 230–285 l |

| Demineralized water tank volume | 2 050 l |

| Deionized water filtration | 1 800 l / h |

| 13 baths for different cleaning phases | 3× chemical baths |

Industrial equipment consisting of several sequential stations for automated cleaning of larger quantities of parts.

Technical parameters:

| Power supply | 3N/PE 400/230V AC / 50Hz |

| Power consumption | 88,5 kW |

| Overall dimensions | 1,40 × 12,00 × 2,50 m |

| Weight without filling | 3 500 kg |

| Manipulator capacity including basket | 120 kg |

| Bath volume | 260 l |

| Bath dimensions | 450 × 650 × 600 mm |

Equipment for washing various objects using high-frequency sound waves. The washer is suitable for cleaning small parts. The advantage of ultrasonic cleaning is thoroughness and gentleness to the material.

Technical parameters:

| Power consumption | 800 W |

| Volume | 25 l |

| Internal basket dimensions | 500 × 300 × 200 mm |

| Heating | 55 °C |

Enables gentle and efficient drying of parts for cleaning. For storage, it uses a controlled environment with a nitrogen system.

Technical parameters:

| Internal volume | 111 l |

| Temperature range | 5 - 200 °C |

| Internal chamber | Stainless steel DIN 1.4571 (AISI 316 Ti) |

- Inert gas connection

- Needle valve for fine pressure regulation

- Pressure-resistant internal chamber

- Large-area door overpressure valve "Ventiflex"

- Version for clean production facilities

Used for Residual Gas Analysis (RGA), which represents a sophisticated process of examining gas concentration in a precisely defined space.

The Prisma Pro spectrometer is a professional solution for accurate and reliable residual gas analysis in vacuum systems.

Technical parameters:

| Range | 1 - 200 amu |

| Maximum operating pressure | 5 × 10 - 5 Pa |

| Ion source | open, 2 threads |

| Filaments | Iridium, coated Y2O3 |

| Filament | wolfram |

| Flange | DN 40 CF-F |

The ASM 340 dry helium leak detector is a dedicated instrument for precise localization of vacuum leaks. It is used to test vacuum chambers, valves, parts, and vacuum assemblies.

Technical parameters:

| Dimensions | 547 × 375 × 389 mm |

| Connection | Flange DN 25 ISO-KF |

| Minimum He leak detection | 1 × 10-9 mbar*l/s |

| Pumping speed of backing pump | 56,60 l/min |

| Power consumption | 600 W |

Technical parameters:

| Dimensions | 556 × 304 × 460 mm |

| Weight | 31 kg |

| Connection | Flange DN 25 ISO-KF |

| Minimum He leak detection | 1 × 10-7 mbar*l/s |

| Pumping speed of external backing pump | 125 l/min |

| Power consumption | 400 VA |

Technical parameters:

| Dimensions | 548 × 360 × 420 mm |

| Weight | 34 kg |

| Connection | příruba DN 25 ISO-KF |

| Minimum He leak detection | <5 × 10-8 mbar*l/s |

| Pumping speed of external backing pump | 125 l/min |

| Power consumption | 350 VA |

- Original Prusa MK4S

- Original Prusa i3 MK3S + MMU3 kit bundle

- Original Prusa XL

- Markforged X7

- Formlabs Form 3

- Formlabs Fuse 1

- EinScan Pro HD 3D scanner

Specially designed for removing residual (flammable) dust when blasting 3D printed plastic parts.

Distribution of gaseous nitrogen for technologies and for creating suitable cleaning and storage conditions.

Technical parameters:

| Pressure vessel type | VT6/18 |

| Main air vaporizer type | AV6M |

| Maximum allowable working pressure | 12 bar |

| Nitrogen purity 5.0 | ≥ 99,999 % |

| Operating temperature | -196 °C |

| Maximum gas flow rate | 80 m3/h |

| Automatic control operating range | 0,2 - 1,2 MPa |